China Optical Lens Blanks Semi Finished Factories – Prescription laboratories transform 1.56 semi-finished lenses into 1.56 finished lenses – YOLI

China Optical Lens Blanks Semi Finished Factories – Prescription laboratories transform 1.56 semi-finished lenses into 1.56 finished lenses – YOLI Detail:

What Semi Finished Lens Blanks Can do?

Spectacle lenses production units that transform semi-finished lenses into finished lenses according the precise characteristics of a prescription.

The customization work of laboratories enables us to provide a wide variation of optical combinations for wearer needs, especially as regards the correction of presbyopia. Laboratories are responsible for surfacing (grinding and polishing) and coating (coloring, anti-scratch, anti-reflective, anti-smudge etc.) the lenses.

The Differences Between 1.50 and 1.56 Lenses?

The difference between 1.56 mid-index and 1.50 standard lenses is thinness.

Lenses with this index reduce lens thickness by 15 percent.

Full-rim eyewear frames/glasses worn during sports activities are most suitable for this lens index.

What is a freeform lens?

A freeform lens normally has a spherical front surface and a complex, three-dimensional back surface which incorporates the patient’s prescription. In the case of a freeform progressive lens, the back surface geometry includes the progressive design.

The freeform process utilises semi-finished spherical lenses which are readily available in a wide range of base curves and indices. These lenses are accurately machined on the back side using state-of-the-art generating and polishing equipment to create the exact prescription surface.

• the front surface is a simple spherical surface

• the back surface is a complex three-dimensional surface

Technology for freeform lenses

• Provides the flexibility to offer a wider range of high level products, even for the smaller optical laboratory

• Only requires a stock of semi-finished spheres in each material from any quality source

• Lab management is simplified with significantly fewer SKUs

• Progressive surface is closer to the eye – providing broader fields of view in the corridor and reading area

• Accurately reproduces the intended progressive design

• Prescription accuracy is not limited by the tooling steps available in the laboratory

• Accurate prescription alignment is guaranteed

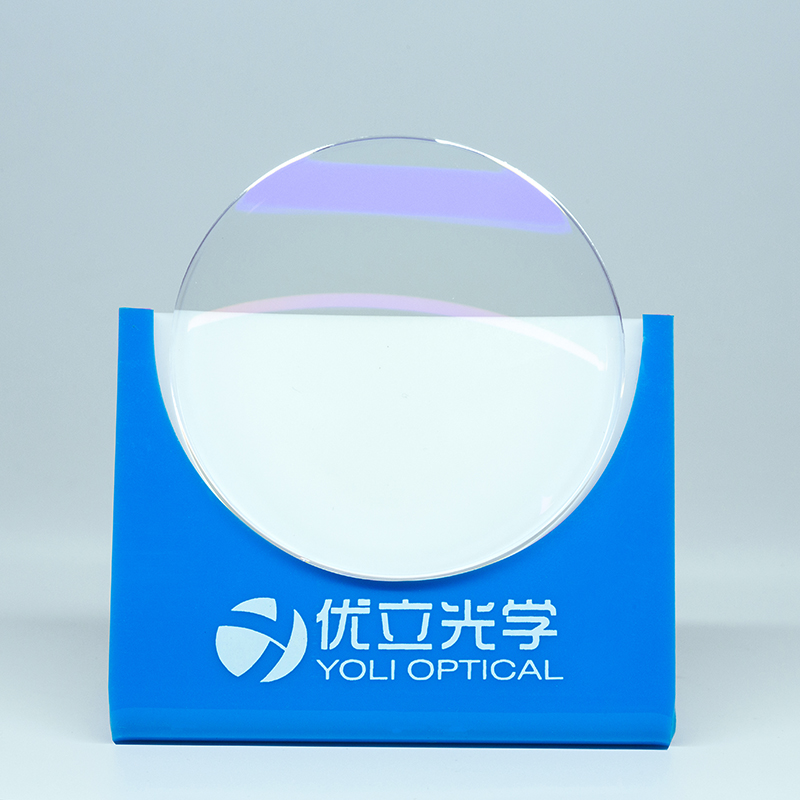

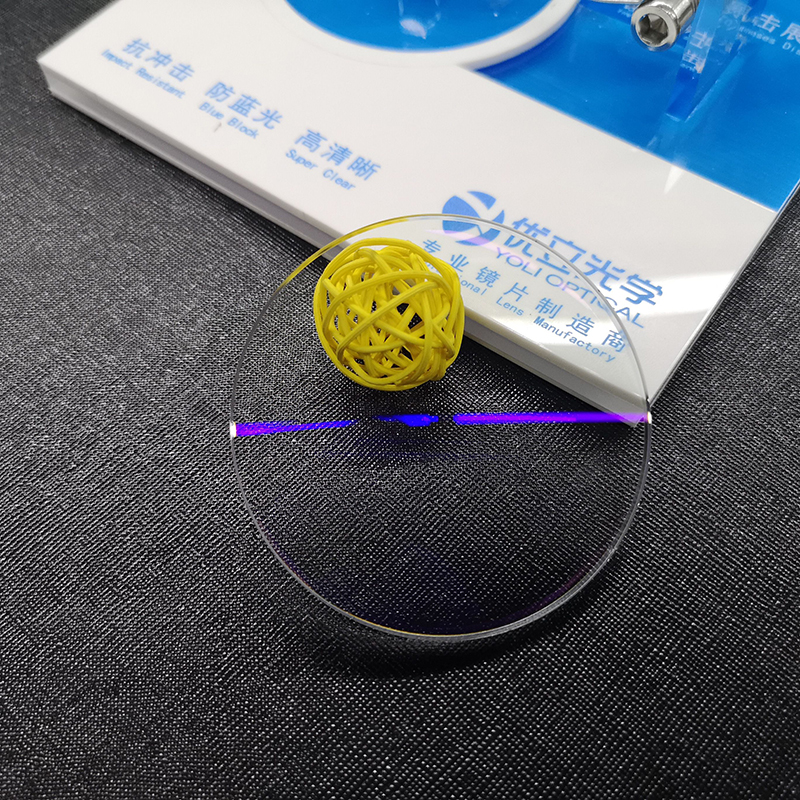

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for China Optical Lens Blanks Semi Finished Factories – Prescription laboratories transform 1.56 semi-finished lenses into 1.56 finished lenses – YOLI , The product will supply to all over the world, such as: Norway, Riyadh, Barcelona, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information and we will offer you competitive price list then.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.