China Semi Finished Optical Lens Blanks Company – 1.67 Semi Finished Lens Blanks Provide a Wide Variation of Optical Combinations for Wearer Needs – YOLI

China Semi Finished Optical Lens Blanks Company – 1.67 Semi Finished Lens Blanks Provide a Wide Variation of Optical Combinations for Wearer Needs – YOLI Detail:

What Semi Finished Lens Blanks Can do?

Spectacle lenses production units that transform semi-finished lenses into finished lenses according the precise characteristics of a prescription.

The customization work of laboratories enables us to provide a wide variation of optical combinations for wearer needs, especially as regards the correction of presbyopia. Laboratories are responsible for surfacing (grinding and polishing) and coating (coloring, anti-scratch, anti-reflective, anti-smudge etc.) the lenses.

Advantages of High-Index Lenses

·Thinner. Because of their ability to bend light more efficiently, high-index lenses for nearsightedness have thinner edges than lenses with the same prescription power that are made of conventional plastic material.

·Lighter. Thinner edges require less lens material, which reduces the overall weight of the lenses. Lenses made of high-index plastic are lighter than the same lenses made in conventional plastic, so they’re more comfortable to wear.

Technology for freeform lenses

• Provides the flexibility to offer a wider range of high level products, even for the smaller optical laboratory

• Only requires a stock of semi-finished spheres in each material from any quality source

• Lab management is simplified with significantly fewer SKUs

• Progressive surface is closer to the eye – providing broader fields of view in the corridor and reading area

• Accurately reproduces the intended progressive design

• Prescription accuracy is not limited by the tooling steps available in the laboratory

• Accurate prescription alignment is guaranteed

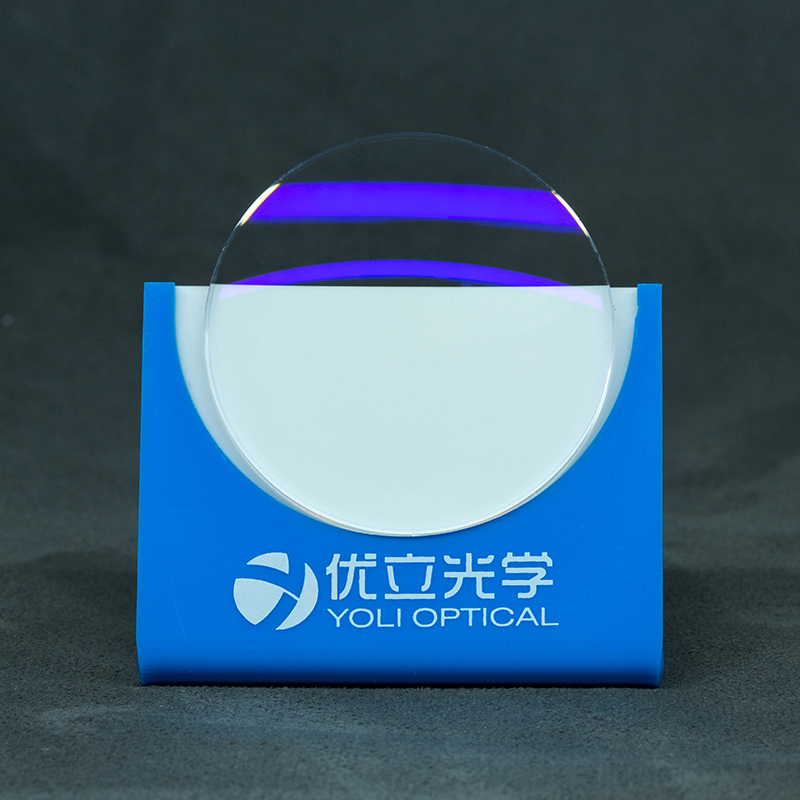

Product detail pictures:

Related Product Guide:

Well-run devices, expert profits group, and better after-sales companies; We have been also a unified huge family, everybody keep on with the organization worth "unification, determination, tolerance" for China Semi Finished Optical Lens Blanks Company – 1.67 Semi Finished Lens Blanks Provide a Wide Variation of Optical Combinations for Wearer Needs – YOLI , The product will supply to all over the world, such as: Poland, Marseille, Rome, With the highest standards of product quality and service, our products have been exported to more than 25 countries like the USA, CANADA, GERMANY, FRANCE, UAE, Malaysia and so on.We are very pleased to serve customers from all over the world!

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!