Wholesale Optical Lens Blanks Semi Finished Suppliers – Polycarbonate Semi Finished Spin Coat Photochromic Lens Blanks – YOLI

Wholesale Optical Lens Blanks Semi Finished Suppliers – Polycarbonate Semi Finished Spin Coat Photochromic Lens Blanks – YOLI Detail:

Why Polycarbonate Lenses?

When it comes to eye safety, polycarbonate and Trivex lenses should be the first options you consider. Not only are they thinner and lighter than other lens materials, but they are 10 times more impact-resistant than ordinary plastic or glass lenses. They also provide 100% protection from UV rays.

These characteristics are especially key when you are considering purchasing sports or children’s eyewear but relevant for all glasses lenses. Both polycarbonate and Trivex lenses are safe and convenient choices for each, but they differ in some areas, offering a slightly varied optical experience.

What are photochromic lenses?

Photochromic lenses are light-adaptive lenses that adjust themselves to different lighting conditions. When indoors, the lenses are clear and when exposed to sunlight, they turn dark in less than a minute.

Intelligent color change

The darkness of the after-changing color of photochromic lenses are decided by the intensity of ultraviolet light.

The photochromic lens can adapt to changing light, so your eyes don’t have to do this. Wearing this kind of lens will help your eyes relax a bit.

Why polycarbonate lenses?

Thinner and lighter than plastic, polycarbonate (impact-resistant) lenses are shatter-proof and provide 100% UV protection, making them the optimal choice for kids and active adults. They’re also ideal for strong prescriptions since they do not add thickness when correcting vision, minimizing any distortion.

What is a freeform lens?

A freeform lens normally has a spherical front surface and a complex, three-dimensional back surface which incorporates the patient’s prescription. In the case of a freeform progressive lens, the back surface geometry includes the progressive design.

The freeform process utilises semi-finished spherical lenses which are readily available in a wide range of base curves and indices. These lenses are accurately machined on the back side using state-of-the-art generating and polishing equipment to create the exact prescription surface.

• the front surface is a simple spherical surface

• the back surface is a complex three-dimensional surface

Technology for freeform lenses

• Provides the flexibility to offer a wider range of high level products, even for the smaller optical laboratory

• Only requires a stock of semi-finished spheres in each material from any quality source

• Lab management is simplified with significantly fewer SKUs

• Progressive surface is closer to the eye – providing broader fields of view in the corridor and reading area

• Accurately reproduces the intended progressive design

• Prescription accuracy is not limited by the tooling steps available in the laboratory

• Accurate prescription alignment is guaranteed

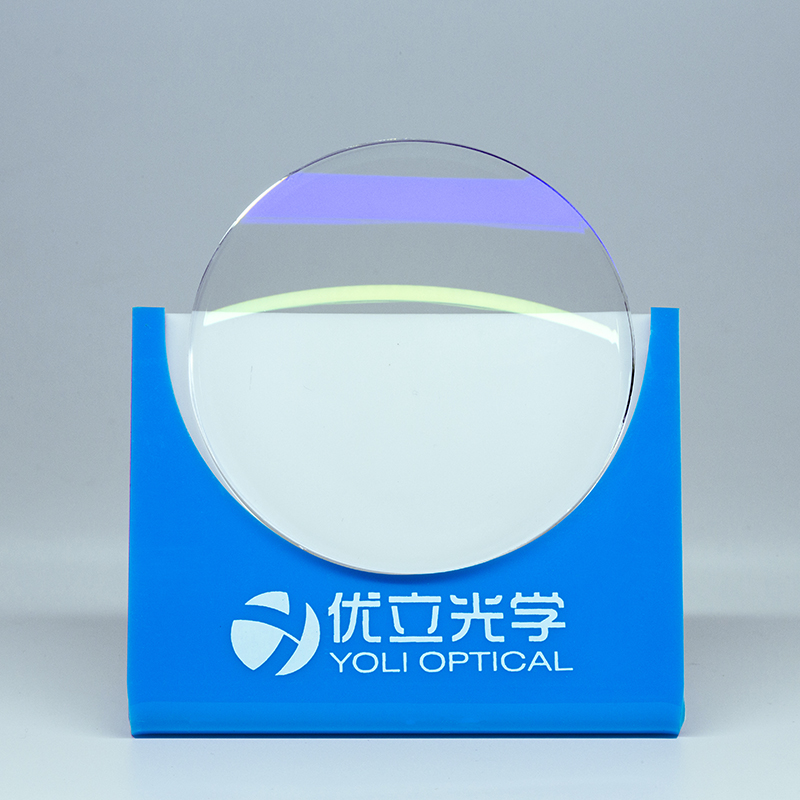

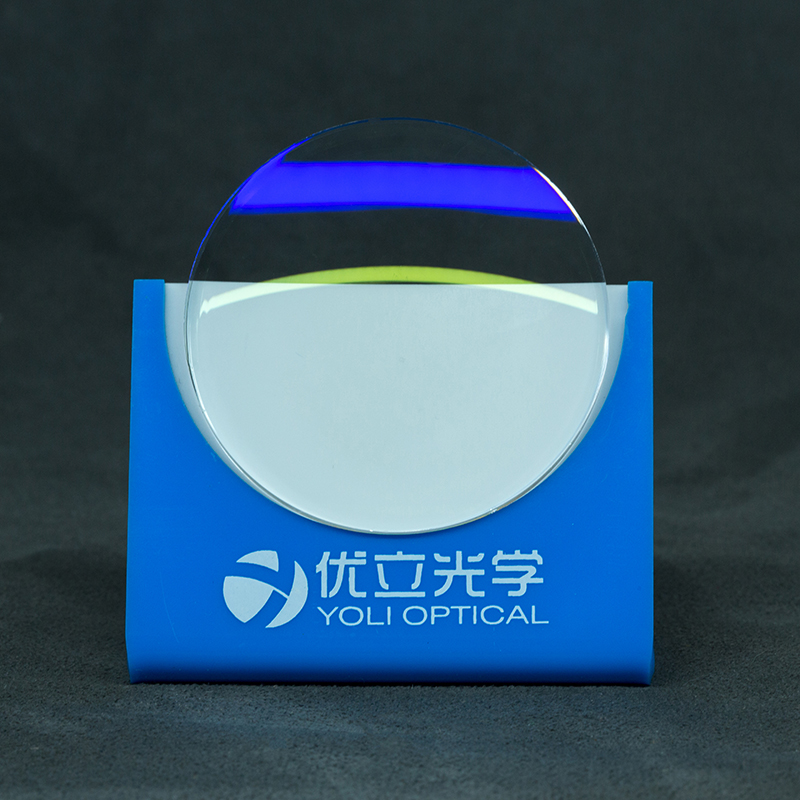

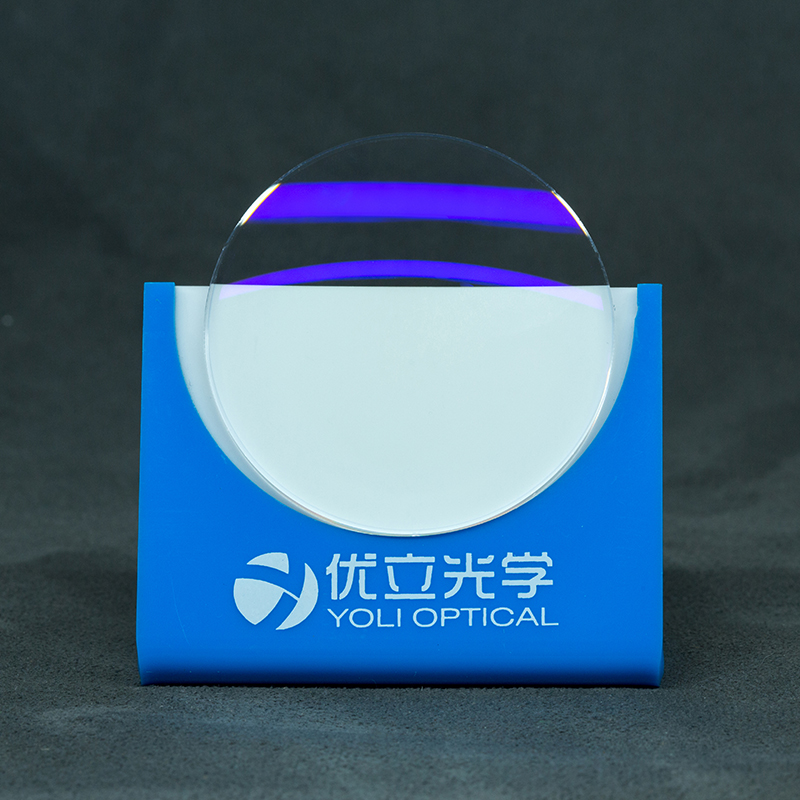

Product detail pictures:

Related Product Guide:

Our mission will be to become an innovative supplier of high-tech digital and communication devices by furnishing benefit added structure, world-class manufacturing, and service capabilities for Wholesale Optical Lens Blanks Semi Finished Suppliers – Polycarbonate Semi Finished Spin Coat Photochromic Lens Blanks – YOLI , The product will supply to all over the world, such as: Greece, Holland, Kyrgyzstan, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part products. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.