Wholesale Photochromic Lenses Companies – 1.60MR-8 Spin Coat Photochromic – YOLI

Wholesale Photochromic Lenses Companies – 1.60MR-8 Spin Coat Photochromic – YOLI Detail:

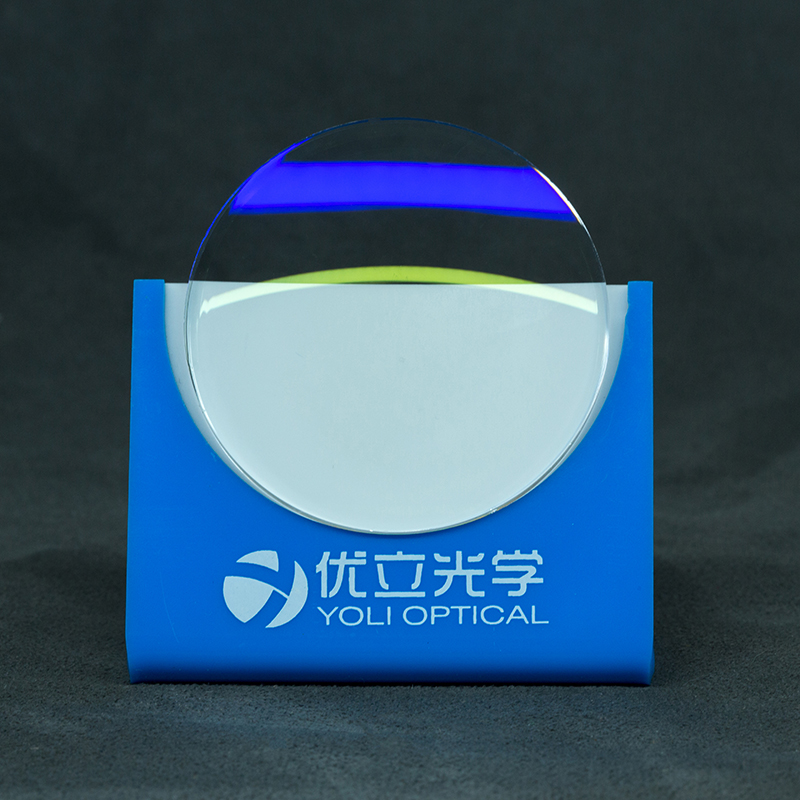

The Photochromic Spin Coat Technology

Spin coating technique is used for making a thin coating on relatively flat substrates. The solution of material to be coated is deposited onto the substrate which is spun off at a high velocity in a range of 1000-8000 rpm and leaving a uniform layer.

Spin-coating technology makes the photochromic coating on the surface of lens, so color only changes on lenses surface, while in-mass technology make the whole lens change color.

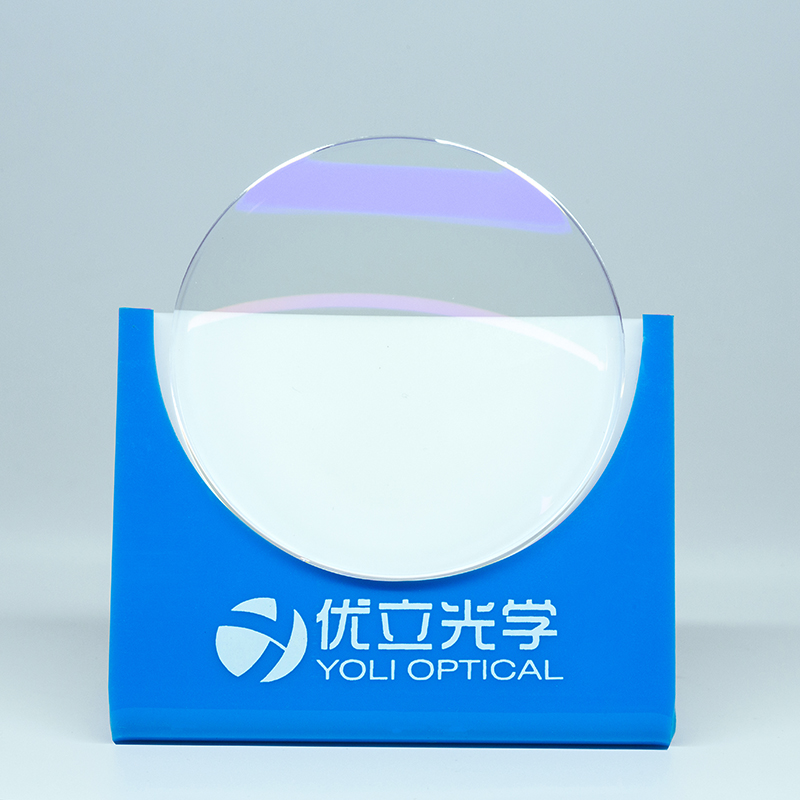

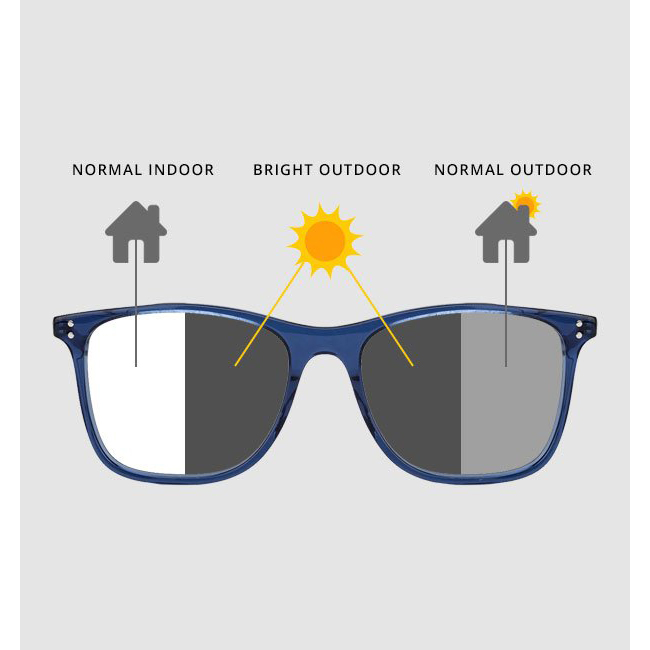

How Do Spin Coat Photochromic Lenses Work?

They are lenses that adapt automatically to changing UV light conditions. They provide protection against glare when worn in brightly lit outdoor conditions, and then return to a transparent state when the wearer moves back indoors. This transition doesn’t happen immediately, however. The change can take up to 2-4 minutes to fully occur.

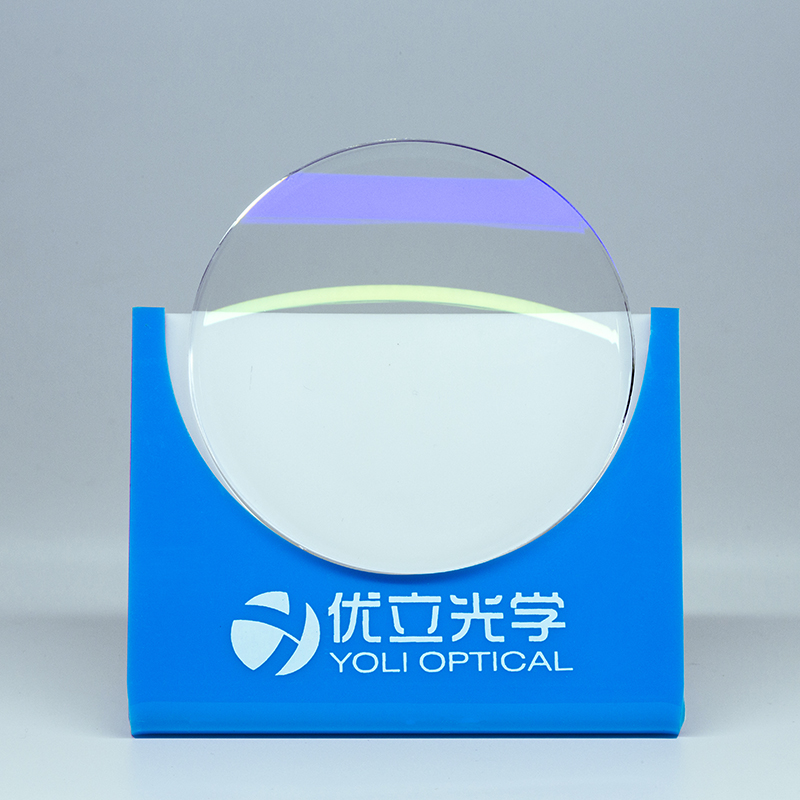

Protect Eyes With Blue Block Lens

Spin Coat Photochromic Lenses is available in blue block and non blue block.

Our blue block lens absorbs harmful UV rays and high energy Blue Light. It is a neutral color-balanced substrate, blended in the lens material while the lens is casted. It is completely normal for lenses to develop a slight tint of yellow over time. It doesn’t alter the inherent properties of the lens material, but ensures a comfortable vision and enhanced protection to the eyes by absorbing UV and high energy Blue light entering the lens.

Advantages of 1.60 MR-8 Material

Compared to the standard 1.60, Mitsui series MR-8 material is easier to drill and absorbs tints more effectively. We recommend this material for rimless glazing.

The MR-8 is simply the best balanced high index lens material in the market, as it possesses excellent physical properties, including high refractive index, high Abbe number, low specific gravity and high impact resistance.

Product detail pictures:

Related Product Guide:

We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for Wholesale Photochromic Lenses Companies – 1.60MR-8 Spin Coat Photochromic – YOLI , The product will supply to all over the world, such as: Bolivia, Florence, Qatar, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.