Wholesale Semi Finished Optical Lens Blanks Companies – Highly Recommend 1.60 MR-8 Semi Finished Ophthalmic Lenses Blanks – YOLI

Wholesale Semi Finished Optical Lens Blanks Companies – Highly Recommend 1.60 MR-8 Semi Finished Ophthalmic Lenses Blanks – YOLI Detail:

What Semi Finished Lens Blanks Can do?

Spectacle lenses production units that transform semi-finished lenses into finished lenses according the precise characteristics of a prescription.

The customization work of laboratories enables us to provide a wide variation of optical combinations for wearer needs, especially as regards the correction of presbyopia. Laboratories are responsible for surfacing (grinding and polishing) and coating (coloring, anti-scratch, anti-reflective, anti-smudge etc.) the lenses.

Why Highly Recommend MR-8?

Refractive Index 1.60

The best balanced high index lens material with the largest share of refractive index 1.60 lens material

market. MR-8 is suited to any strength ophthalmic lens and is a new standard in ophthalmic lens material.

Comparison of thickness of 1.60 MR-8 lens and 1.50 CR-39 lenses (-6.00D)

Abbe Number: A number that determinesthe viewing comfort of glasses

| MR-8 | Polycarbonate | Acrylic | CR-39 | Crown glass | |||||||||||

| Refractive index | 1.60 | 1.59 | 1.60 | 1.50 | 1.52 | ||||||||||

| Abbe number | 41 | 28~30 | 32 | 58 | 59 | ||||||||||

·Both high refractive index and high Abbe number provide optical performance similar to glass lenses.

·High Abbe number material such as MR-8 minimizes the prism effect (chromatic aberration) of lenses and provides comfortable use for all wearers.

Strain Free

MR-8 resin is uniformly polymerized in a glass mold. Compared to injection molded polycarbonate lenses,

MR-8 resin lenses show minimal stress strain and offer stress free clear vision.

Stress Strain Observation

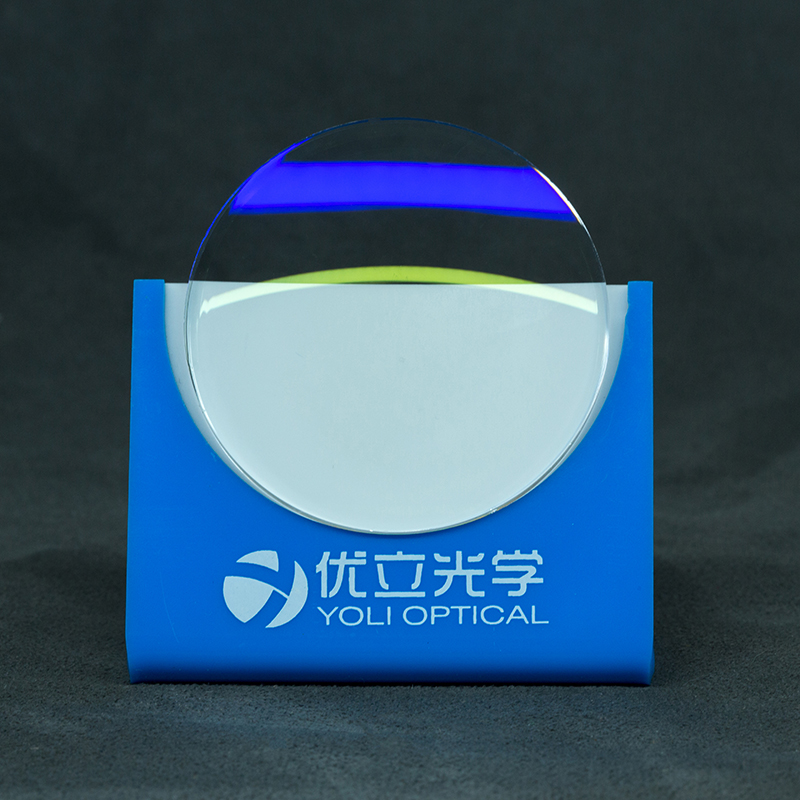

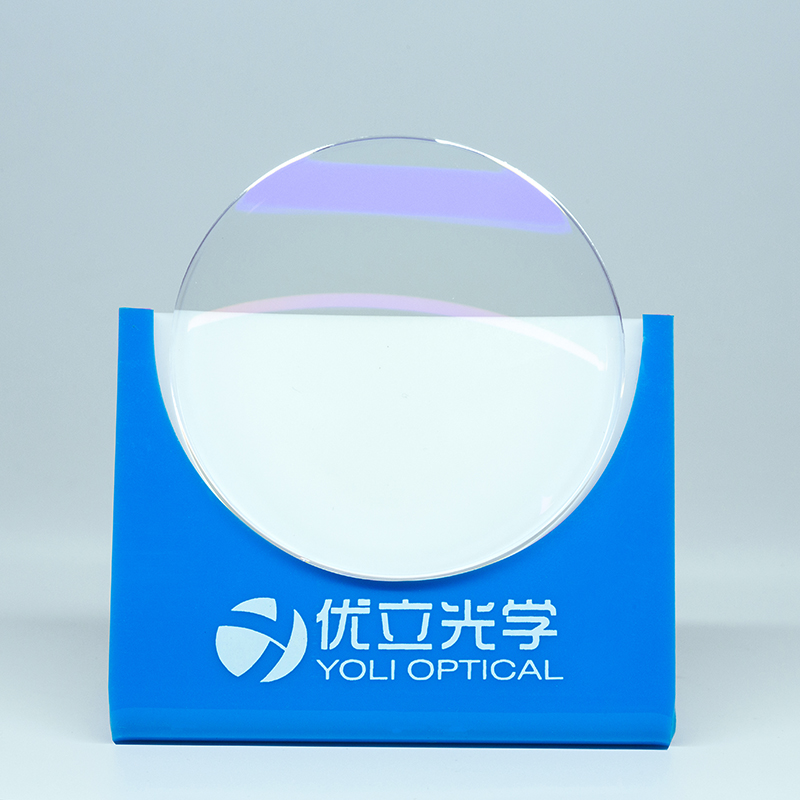

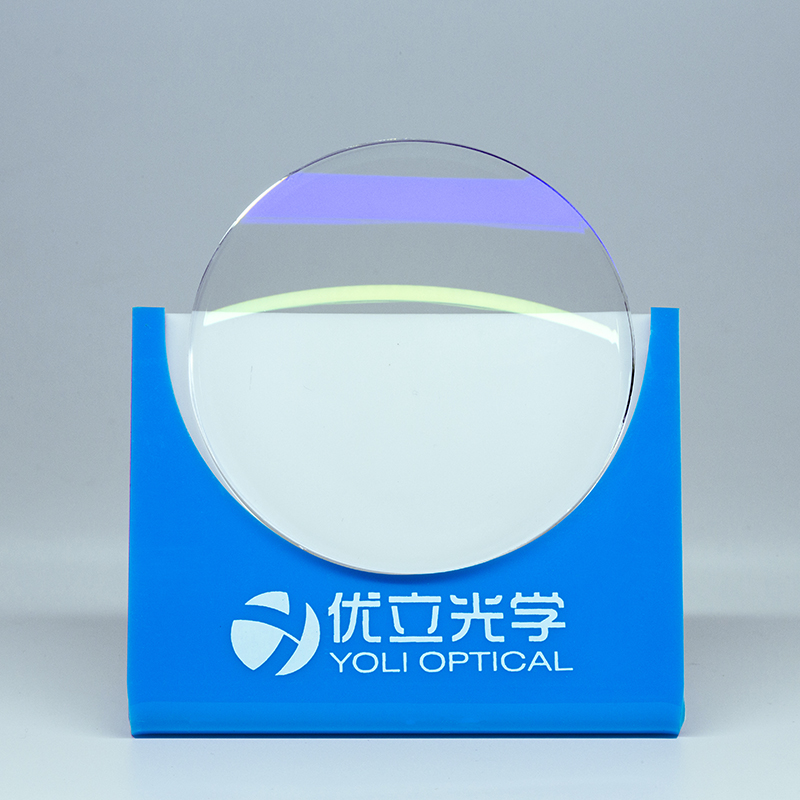

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by people and can fulfill repeatedly altering economic and social wants of Wholesale Semi Finished Optical Lens Blanks Companies – Highly Recommend 1.60 MR-8 Semi Finished Ophthalmic Lenses Blanks – YOLI , The product will supply to all over the world, such as: Rwanda, Kenya, New Zealand, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!